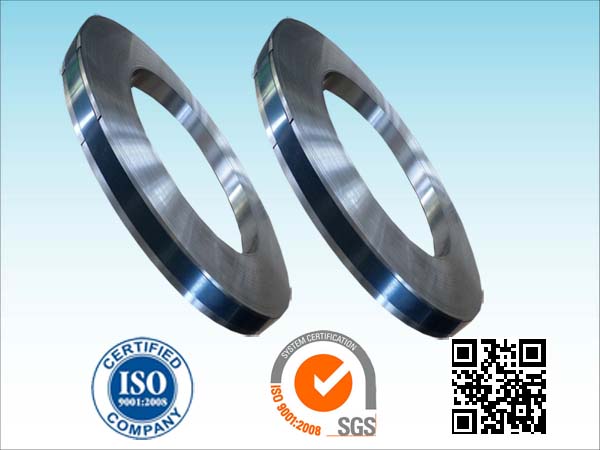

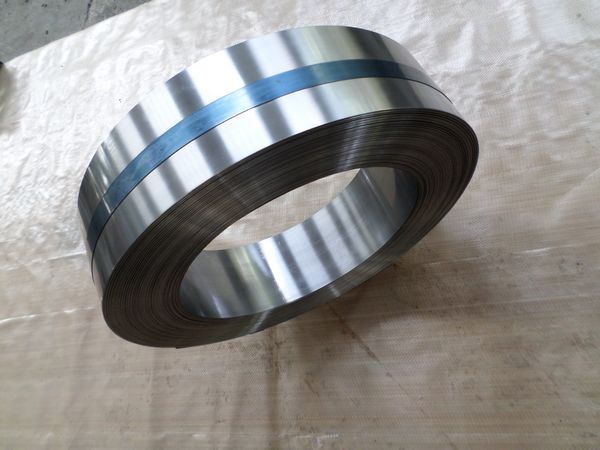

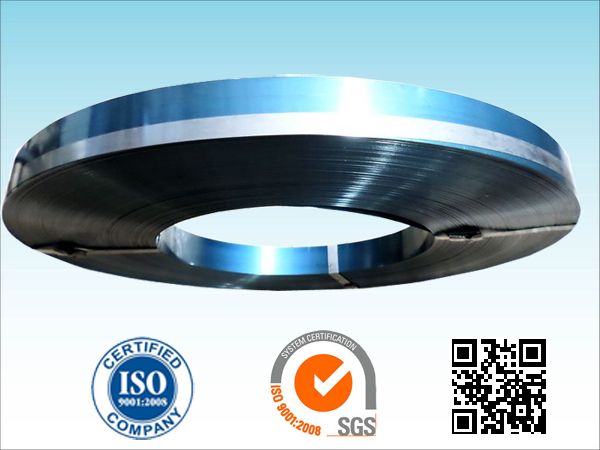

Bandsaw blade high carbon steel strips is produced by the best domestic raw material with ck67/ck75/ck85.and do the process with heating treatment with hardened and tempered through controlling heating and coolling process.this process of hardending and tempering improve the mechanical propeties of bandsaw blade high carbon steel strips.the hardenign process involves heating the steel strip to above the critical transformation temperature for the given grade and then rapidly cooling,the problem here is that the bandsaw blade high carbon steel strip in this condition is extremely brittle and in this way requires further treament in form of tempering for a period time without oxidation,these type of steel strip is widely use in bandsaw blade,woodsaw blade.etc

Main SPECIFICATION

standard |

DIN AISI |

grade |

ck67/ck75/ck85 |

thickness |

0.20-2.5mm+/-0.03mm |

width |

4-300mm+/-0.05mm |

surface |

polished-blue,polished-whtie,unpolished |

hardness |

44-46hrc |

edge |

rounded slited,square |

MOQ |

3000KG |

coil ID |

300-500mm |

coil OD |

max1000mm,according to your requirement |

tensile strength |

540-1275N/mm2 |

yield strength |

370-1175N/mm2 |

How can make sure the best flatness?

1)it will pass the specific machine which is professional to make the flatness according to the customer's requriement

2)in our factory,we have the best equipment and skill experts to produce steel strip,contorlling strictly every produciton of line

How can we controll the quality

1)raw material

the acceptance or rejection of raw material is normally the duty of the analytical chemists Dept,their duty is to decide whether the material is good or not,inspection is usually combined with sampling and is the most important part of raw material inspection.

2)process of manufacture

GWYL is a professional and original producer and exporter over 10 year,it has the best skilled experts and compelte equipment to product high carbon spring steel strip,controlling every production line

3)inspection of the finished product :QC control strictly,all the order of the finished product is inspected by the QC,including check the surface,hardness,thickness,width,edge,ipackage and so on.if not meet the customer's requirement by inspected,it will be not pass and reproduct.