C75 C75S carbon spring steel blade for plaster trowels

1.How to guarantee the right even hardness

We have the skill experts who reponsible to control the temerature when doing the heat treatment with hardened and tempered,it will choose very close digit to make it ,for example, if the customer require 47-52HRC, we will prouce the closed 49-50hrc,expercially controlling in 49.5hrc,in this way can make sure the uniform and right harddness

2.How to make sure the good flatness and straightness

We have the lead furnace and drawing machine to ensure the better flatness and straightness,and our levelling process stretches sheet steel in coil form by pulling it beyond its yield point,top-to-bottom and edge-to-edge.Following this procedure,the material should be perfectly flat and relatively free of intenal stresses

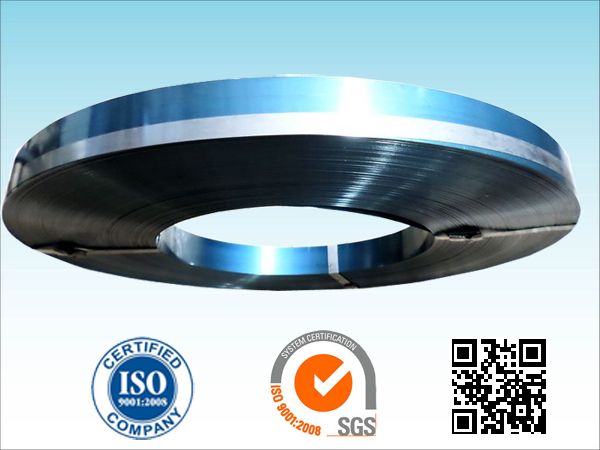

3. How to assure the good shining or blue polising Surface

It will be made the second the polishing

Regular size as request

| 0.21x101.6mm | 0.25x101.6mm | 0.35x100mm | 0.33x180mm | 0.4x100mm | 0.5x100mm |

| 0.7x100mm | 0.7x120mm | 0.7x130mm | 0.8x130mm | 1.0x100mm | 1.0x200mm |

| 1.5x200mm | 0.4x120mm | 11.2x200mm | 1.2x180mm | 0.8x150mm | 0.3x120mm |

| 0.5x120mm | 0.6x120mm | 0.8x150mm | 0.6x200mm | etc |

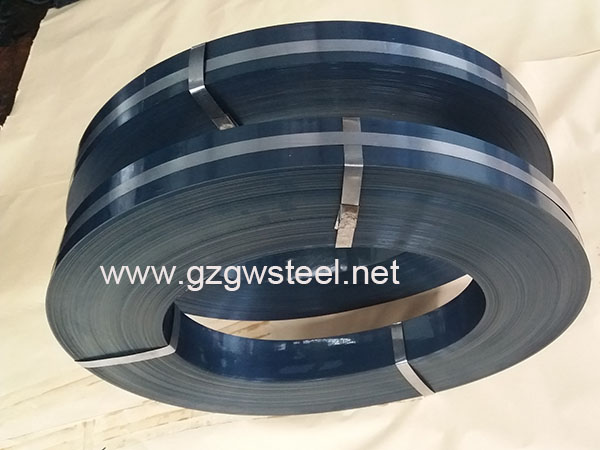

Package:each coils with light oil and plastic film then wrapped in anti-rust paper with metallic pallet