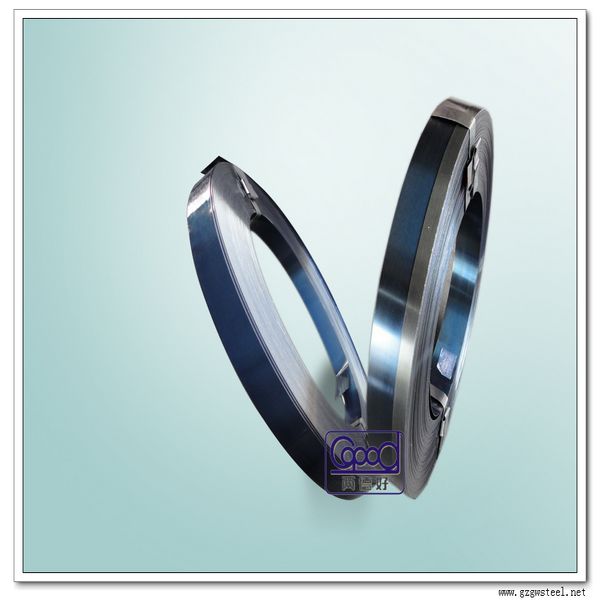

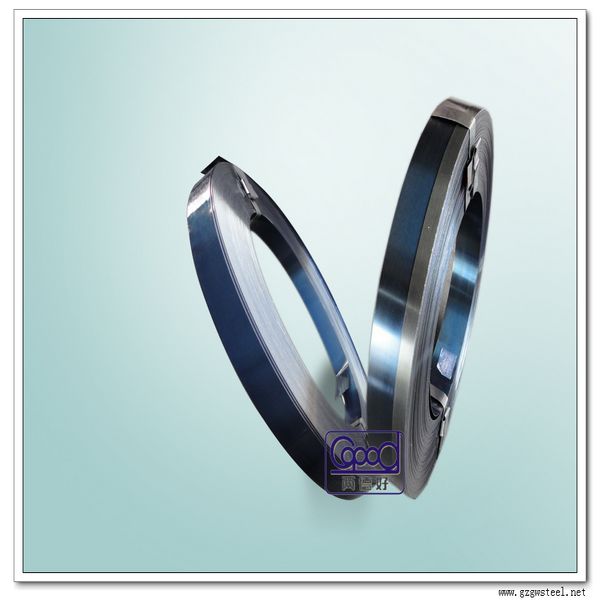

hardened and tempered steel strip

Hardened and Tempered Steel Strip (also known as hardened and tempered carbon spring steel strip) is the basic raw material from which many different components are made, substantially being roller shutter spring,roller door spring applications ranging from shutter spring,hand building tools,leaf sprig,shoes metal accessory,agriculture tools, masonry tools etc. These strip products are a speciality of the Company and considerable plant development has taken place in recent years to facilitate a very wide range of dimensions, mechanical properties and coil weights. Hardened and Tempered Steel Strip gauges of between 0.20mm and 2.50mm can be processed and, depending on the appropriate combination to suit the process equipment, strip widths of between 10 mm to 300 mm are produced. The facilities also allow up to 200-300 kg coils to be produced though most are well below this, being governed by a very approximate relationship of 200kg per 40-80mm of width.

The steel grades involved in this range of Hardened and Tempered Steel Strip products are the medium/higher carbon steels and alloy steels, with the overall carbon range being 0.45 - 0.75%. Within this range are closely defined standards such as, in DIN CK45 CK50 CK55 CK60 CK67 CK70 CK75,specifications. Globally, these would be recognised as say AISI grades 1045, 1050,1055, 1060, 1065,1070, 1074,and 6150 and in the relatively recent European specification EN 10132-4 as C55S, C60S, C67S, C75S, and 51CrV4.

Technically, the Hardened and Tempered Steel Strip produced by the Company is that in the martensitic condition where high levels of hardness are achieved which are then accompanied by the appropriate ductility and shock resistance properties the user industries require. The heat treatments involved are carried out on continuous production lines, each line containing 2 furnaces, the first of which heats the steel to temperatures from which, after rapid cooling, the steel is fully hardened. At this stage the steel, whilst very hard, is also very brittle and it is the second furnace in the production line, the tempering furnace that reheats the steel to temperatures at which the steel is softened slightly and develops some ductility and impact resistance. Typically, steel is hardened from temperatures of 800/920°C whereas the tempering process uses temperatures of 350 - 600°C and the selection of temperatures in this range is critical as it determines the final hardness (and tensile strength) of the steel. With the range of steel grades involved hardness levels of between 29-55HRC are possible, the steels with the highest carbon levels being most suitable for hardening to the upper ranges of hardness. With accurate tempering temperature control the range of hardness achieved on any one item can be restricted to 29-55HRC. Thus, across the whole range of high carbon steels, a large number of very specifically-tailored strip products can be engineered for particular end-use applications.

These steels are most commonly produced with sheared edges and a slightly oxidised blue black (also called blue grey) finish, as these conditions are fully acceptable in engineering component manufacture. Steel strip with enhanced properties can be produced by edge machining the strip, either before or after the hardening and tempering process. Edge-dressed strip is material where the edge condition from the previous slitting process has been removed, in the Company's case by a very effective in-line, 2-sided machining process which removes the sheared edges which naturally contain a level of micro-cracks and are also of a relatively rough nature. The dressed edge confers a substantial engineering benefit in improved fatigue-resistance properties, this being of particular value in arduous spring-type applications.

The strip edge can be machined to either round or square profiles, round being the preferred profile for fatigue-resistance benefits. A square edge has a more particular application in that it gives a high quality reference plane for use in doctor blade applications where one strip edge is processed to the final blade profile used for example in the paper manufacturing industry.

A further benefit of edge dressing is to increase handling safety aspects where the sheared edges may be considered hazardous to the end applications. Whilst the mechanical properties of the strip are still the dominant factors, there may be personal contact with the end product or where the sheared edge may damage any coverings applied to the product. Examples of this would be where the steel is used in prosthetic limbs or even when covered with fabric such as in photographic reflectors.

The surface finish of Hardened and Tempered Steel Strip products is not too critical in general engineering applications where the normal blue black (also known as blue grey) oxidised finish from the heat treatment is satisfactory. By control of the temperature in the colour tempering furnace oxidised surfaces can also be produced to bring up different colours such as deep blue and yellow/golden/bronze, on a selected basis, and alternatively, steels can be bright polished/grinded where needed, these finishes being as much for cosmetic reasons as for engineering purposes.

Hardened & Tempered Strips of Medium & High carbon steel is Produced with a state of art proccesing faciltiy.